COMPANY PROFILE

Suzhou Xinshida Precision Electronic Technology Co., Ltd. was founded in June 2004. It is a high and new technology enterprise that integrates high-precision mold design, manufacturing, injection molding, stamping molding, spraying assembly, and automation. Our aim is to provide one-stop service, and a complete set of solutions for customers, and to save costs for customers constantly.

The registered capital of the company is RMB 10 million, the investment amount exceeds RMB 60 million, the plant area is about 10,000 square meters, and there're about 120 employees.

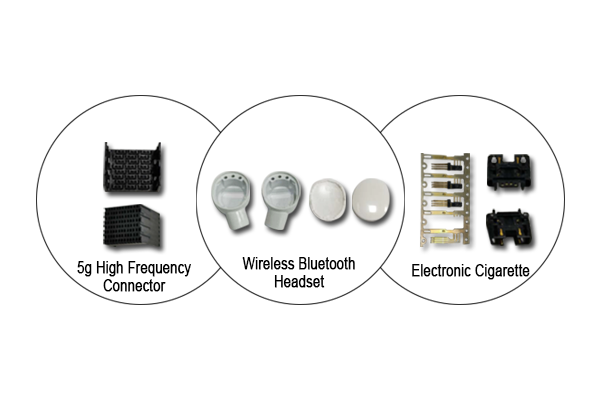

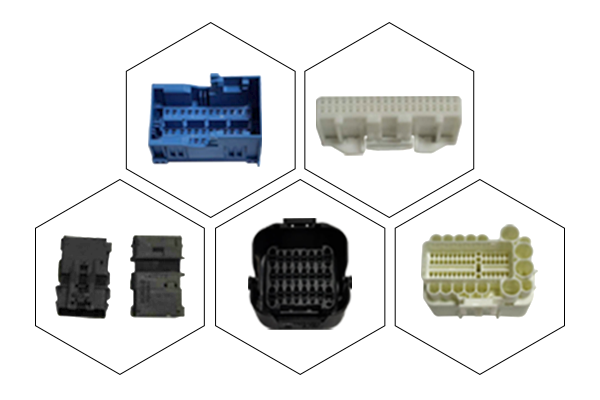

The company's products mainly involve industries such as automobile, medical equipment, mobile phone, computer, household appliances, and intelligent robot.

The company's main customer bases include: TEconnectivity, Molex, DELPHI, P&G, Knowles, OMRON, Ecovacs, Dynapack and other well-known enterprises at home and abroad.

Four Major Core Advantages

At present, the company has 10 mold design engineers, 2 stamping design engineers, and 2 automation design engineers. It is also equipped with several mold assembly engineers, automation electronic control engineers, injection molding process engineers, QE engineers, and FAI measurement engineers. It is specially good at the design and manufacture of molds of gate cut in mold, screw thread core pulling, insert molding, and over molding. Besides, it obtained the qualification of Suzhou Engineering Technology Research Center and the qualification of Suzhou R&D Institution in 2019.

② High precision imported equipment guarantees high quality.

Injection molding equipment: Fanuc precision injection molding machine, and Sumitomo precision injection molding machine, 55 sets in total. All the injection molding auxiliary machines are Kawata machines, 55 sets in total, five-axis manipulators are Yushin manipulators, 55 sets, and there're 55 mold monitors, creating a better standard automated injection molding workshop.

Stamping equipment: Mingzhu and Chenli presses 25T-125T, 6 sets in total.

Mold equipment: Makino, Sodick precision discharge, wire cutting machine, precision CNC machining center, etc., with a machining precision reaching ±0.002mm, 40 sets in total.Testing equipment: Nikon, Hexagon and other precision testing equipment, with precision reaching 0.001mm, 40 sets in total.

③ Professional team and automated production standardThe company's injection molding and stamping production is completely standardized, and the automated production standard integrating automatic material baking, automatic material loading, mold monitoring, and automatic taking out is adopted. The company's mold manufacturing team has more than 10 years of experience, with stable team members, and a semi-automatization mold processing system is adopted by mold manufacturing, with short cycle, high efficiency and obvious cost advantage.

④ Perfect quality assurance system and delivery management system

The company has passed IATF16949:2016 international quality system certification, ISO14001:2015 environmental management system certification, and passed the IECQ QC080000:2017 in 2018. It has a complete management system and a reliable quality assurance system. In addition, it passed the high and new technology enterprise certification in 2018.

The company has always adhered to the operation philosophy of "innovation, pragmatism, and must reach". Based on the "customer-centered and striver-oriented" operation policy, it provides customers with high-quality products and services, and strives to become the best in the industry.

- TEL 0512-52868993

- TOP

Contact: Manager Liu

Contact: Manager Liu Address: No. 129, Huyi Highway, Zifu Community, Guli Town, Changshu City

Address: No. 129, Huyi Highway, Zifu Community, Guli Town, Changshu City Website:www.tnstart.com.cn

Website:www.tnstart.com.cn

Page Copyright: Suzhou Xinshida Precision Electronic Technology Co., Ltd.|

Copyright - 2020 All Rights Reserved.

苏ICP备16000670号

Powered by www.300.cn

Tel:

Tel: Email:

Email: